WHY CHOOSE US

TOP QUALITY LEATHER

Wide range of selection of full-grain and top-grain cow, buffalo, sheep, and goat skin leather from top tannery around the world.

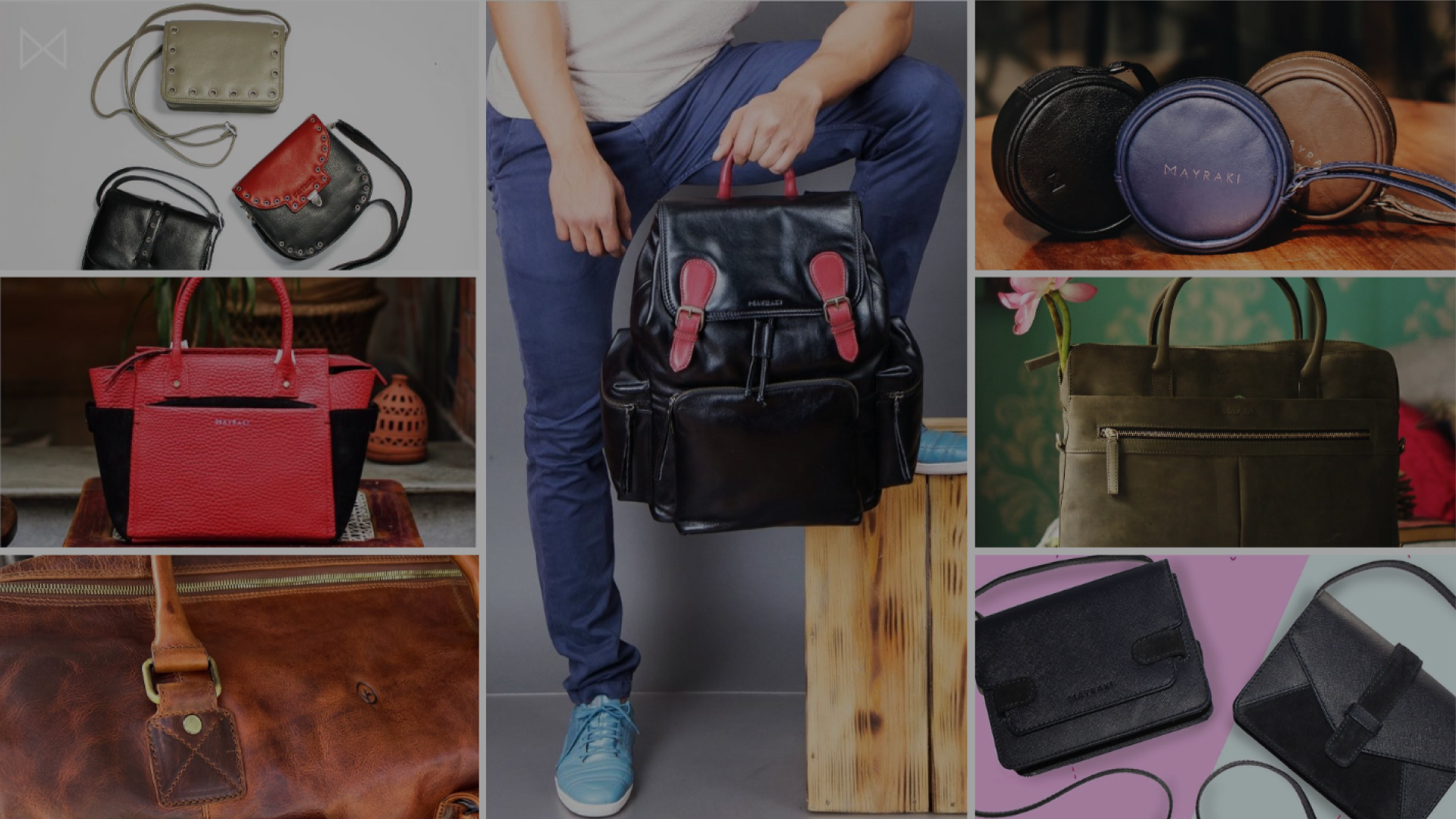

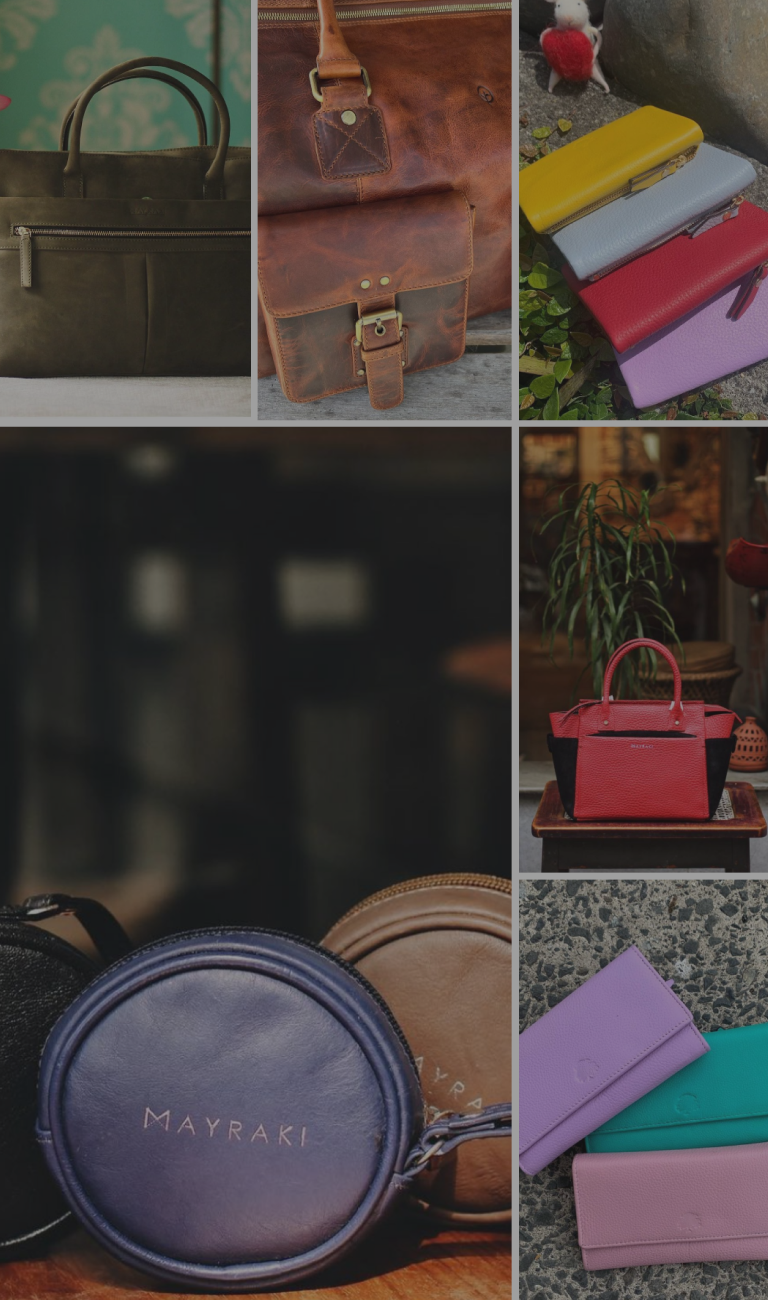

HUGE PRODUCT LINE

We manufacture different product which are made from various speciality leathers, each with its own unique properties and beauty.

SKILLS & EXPERIENCE

Our skilled and experienced craftsmen are hungry for challenging projects and are willing to take projects of any size or complexity.

Hi tech machineries

Hi tech machineries used, Which gives each of the product a high quality finish. Latest technology and updated machineries used hence making the production flow smooth and fast. Hence less dependent on man power and also saving labor cost.

RIGOROUS QUALITY CONTROL

Our tiered quality control system ensures process integrity and product conformance with product specifications at all levels.

CUSTOM MANUFACTURING

We have expertise and experience to manufacture leather products as per specifications provided to fit into customer’s product lines

PRIVATE BESPOKE MANUFACTURING BAGS AND ACCESSORIES

With decades of experience in designing and manufacturing bags & accessories for private labels, companies of any size and individual, we have mastered the art and craft of bags & accessories manufacturing. Our team will guide you through the steps of building a successful leather goods brand. Get in touch to learn more about our private label prototyping services for Purses, clutch, functional bags, work bags, laptop bags, belts or any other leather accessory you desire.

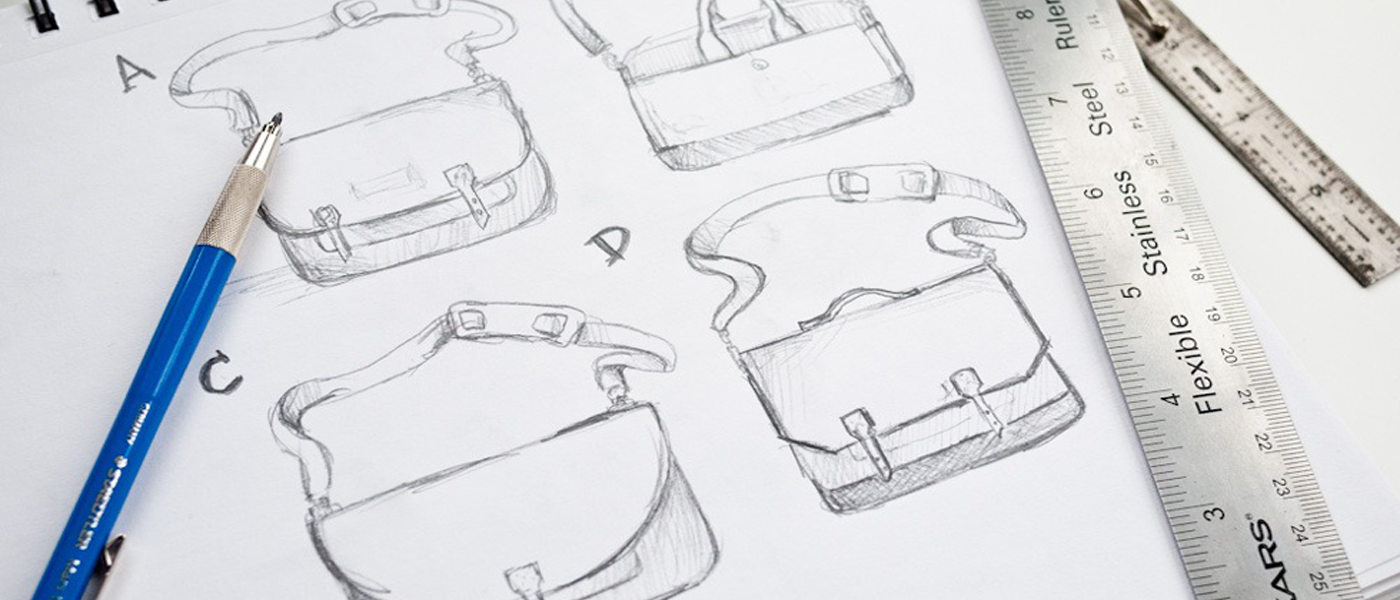

PROTOTYPE DEVELOPMENT

Bring your designs to life with CRESENT LEATHER’s Prototyping services for private labels. This step is crucial to developing a new bag & accessories collection before making a production order.

Our development team will help transfer your designs and requirements into prototypes and real sample products, ready to be manufactured in bulk orders. Samples can also be used to show retail buyers, exhibit them at trade shows or on your website & social media for pre-order.

The prototyping process comprises of technical consultation, material sourcing, 2D pattern making, bag dies development, component sourcing and procurement of hardware elements and embellishments as required.

CONCEPT TO PRODUCTION IN 5 SIMPLE STEPS

1/5

MODEL AND PROTOTYPE

Our artisans translate the fashion

designer’s idea into a prototype.

2/5

SAMPLE

Based on the prototype, we create the best presentation of the product.

3/5

MANUFACTURING

Our lean production processes allow you to order in small or large batch quantities to avoid dead stock.

4/5

QUALITY CONTROL

Each product goes through extensive quality control checks before leaving our facilities to guarantee our pristine craftsmanship.

5/5

SUPPLY CHAIN

We can manage all procurement and delivery flows

MATERIAL SELECTION

Each product that leaves our factory features pristine quality leather and suede, sourced from the best ethical tanneries in Asia. We have a range of colours and textures to suit every type of leather bags and leather accessory. 100% Full grain leather, Vegan leather, special materials and exotic skins can be order as per the clients requirements. Each hide is examined by our craftsmen before production to ensure a smooth touch, great comfort and stunning look.

ON DEMAND, NO MOQ MANUFACTURING

Our no Minimum Order Quantity [MOQ] manufacturing is breaking industry barriers. We can produce 10 or several dozens of bags depending on the clients requirements. We are very startup friendly and provide an end to end solution from concept all the way to production. For production, orders and price is determined on several factors such as bag design, materials used, quantity and level of craftsmanship involved among other things.

ON DEMAND, NO MOQ MANUFACTURING

Our no Minimum Order Quantity [MOQ] manufacturing is breaking industry barriers. We can produce one or several pairs of shoes depending on the clients requirements. We are very startup friendly and provide an end to end solution from concept all the way to production. For production orders, price per pair is determined on several factors such as shoe design, materials used, quantity and level of craftsmanship involved among other things.

FROM PRODUCTION TO DISTRIBUTION

Thanks to the company’s solid supply-chain, we take care of every stage of production: starting with appropriate material choices based on price point and product vision, the process continues with prototype development, carried out internally in the company, followed by sample and bulk production, before final shipment to the customer.

We offer an end-to-end solution and oversee the supply chain process, ensuring quality standards and milestones are met.